The Slurry - 9.5.24

Recently, I’ve been a part of a few conversations with people wanting to learn about the winery and winemaking. When I stand in the winery and look around, I realize to teach something that is a simple passion to me is more complicated than it seems. What rises to the top of the lesson plan is, “How to prepare your yeast.”

Part of being a small batch, garagiste style winemaker is the care taken and enjoyment experienced in each step of the process and the most important step of the entire process is to nurture the yeast.

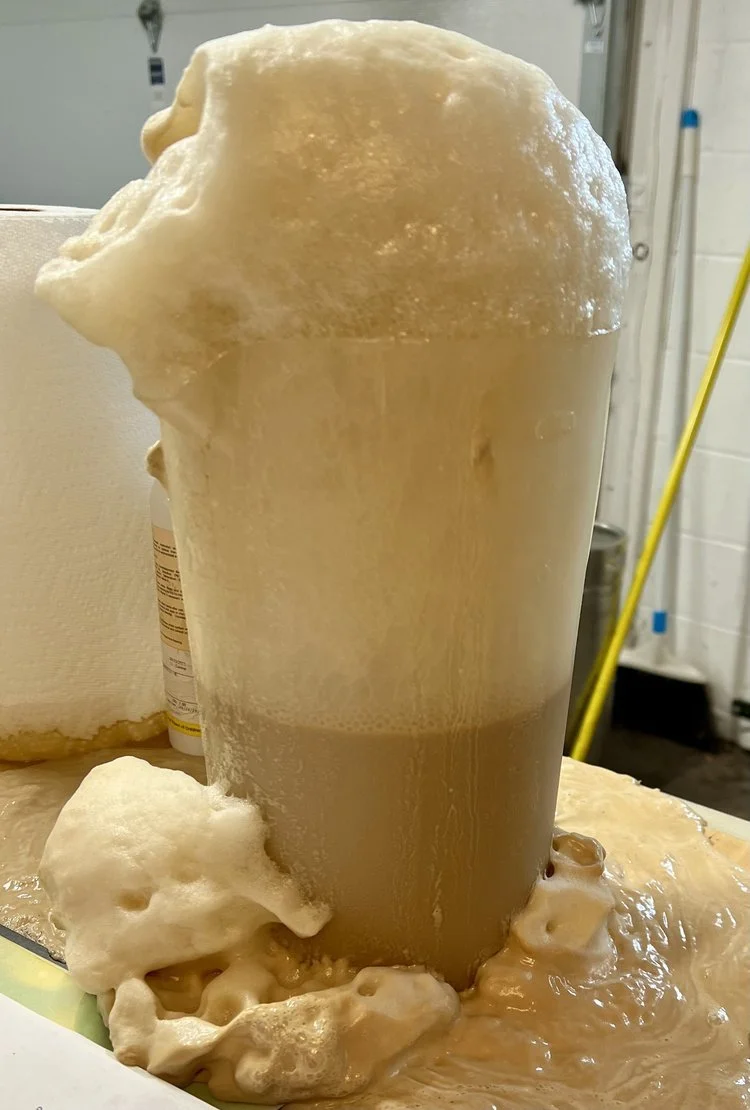

Starting with a yeast nutrient in a beaker, warm (110°F) water is mixed in very gently until all nutrient is dissolved fully. This nutrient slurry must cool to 100°F before folding in the yeast. I’m not sure how much of this gentle stirring is recipe and how much is love but my guess is 50/50.

When the temperature of the mixture drops to 100°F, very gently fold the yeast into the nutrient mixture. This part of the process is waking up the yeast and we want to wake it gently. Continue stirring intermittently until it is slightly warm to touch, and you can see yeast activity.

Yeast cannot be pitched into the must until it is within 10°F of must temperature and must temperature has to be at least 60°F before pitching the yeast or the yeast can be shocked and die. Since the grapes travel in a refrigerated truck, it takes a day or two for the must to come up to 60°F.

When the must and yeast mixture are basically the same temperature, pitch the yeast in and gently mix it into one small area of the must. The next day punch down thoroughly, yet gently, and then cover and wait. This period of time is called “lag”.

Determining the end of lag is fun, too. Removing the cover from the fermentation tub, the top of the must has a dry, warm crust of skins on it similar to a baking a cake or bread. Hover your hand and you can feel the heat of the fermentation. Put your ear to the top of the must and you can hear the crackling of the fermentation. Do not inhale! At this point the must will be off-gassing CO2.

At the end of lag it’s time to mix and add another yeast nutrient slurry to the must and begin punch down (push the skins into the juice) twice a day.

The variety of grape and the type of yeast determine the length of fermentation. We may add slurries of nutrients a few more times throughout the process to ensure completion of fermentation. A stalled fermentation causes sweet wine so all of this has it’s importance.

I hope your slurry is always smooth!

Sharon