Fermentation Experience - 11.3.23

For the next 2 weeks we are making wine! We crushed the grapes on Sunday, pitched the yeast on Tuesday, and Thursday fermentation is in full swing. To create the perfect environment for the yeast to thrive and complete it’s job of converting sugar to alcohol there are a few critical steps.

After testing pH, Total Acid, and sugar in the must, any changes necessary are made to stabilized these numbers so that fermentation goes as smoothly as possible. The must then has to come up to 60° Fahrenheit before the yeast can survive. Once the this happens, nutrients are mixed in warm water to make a nutritious slurry to rehydrate and feed the yeast. After the yeast is added to the warm nutrient slurry, we need it to cool to within 18° of the must temperature before pitching.

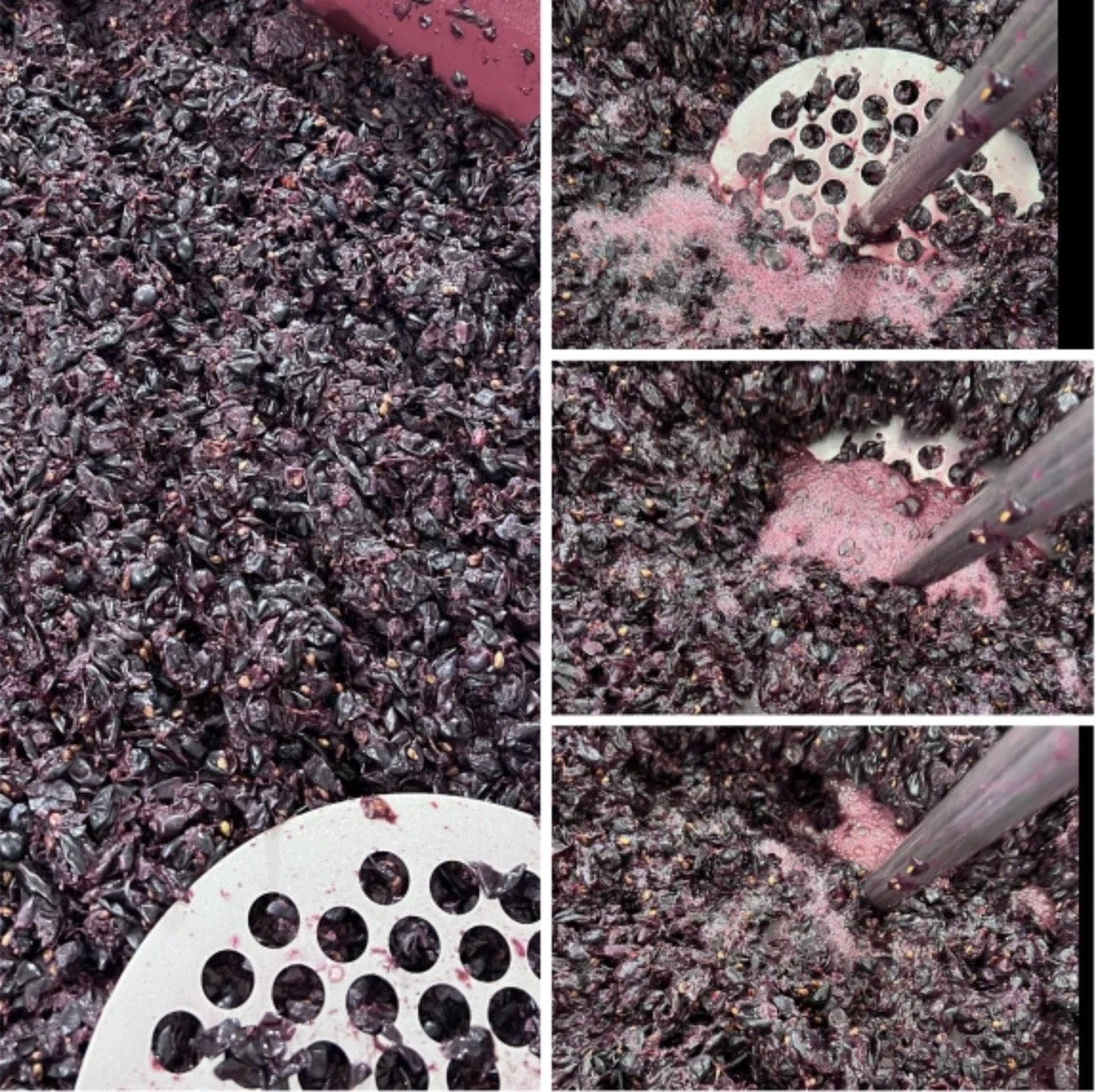

It takes a few hours and dedicated concentration to get these tasks done. Once pitch occurs we wait and watch. We are waiting for the skins to separate from the juice and form a cap on top of the must. This cap looks like the top of a baked cake that has risen, and cracked somewhat, letting you know if is fully baked or in this case letting you know fermentation is underway. Once the cap has formed punch down begins. During the next 2 weeks we continue to add nutrients to the must to feed the yeast.

When peeling the cover off the top of the fermenter you can feel the heat that the fermentation is generating. The smells of the wine-to-be change continually throughout the week and carry from the garage through the breezeway and into the house. During punch down, we take the plunger pictured above and push the skins very gently into the juice. This allows the color and tannins from the skins to permeate the wine. We do this twice a day until the sugar is depleted and fermentation ends. The sounds are so lush, and the colors so beautiful in the must during this process that this is my favorite part of winemaking.

Cheers,

Sharon